Ibhande lensimbi engagqwali elingu-301 liyisici esiyinhloko sokusetshenziswa.Ngenxa yokubekezelela ubulukhuni obukhulu, inkambu yesicelo ibanzi kakhulu.Ibhande lensimbi engagqwali elingu-301 lihambisana nophawu lokuthengisa lwaseShayina olusha: 12Cr17Ni7 kanye nophawu lokuthengisa oludala u-1Cr17Ni7.

Ngenxa yokuthi okuqukethwe kwekhabhoni kungcono kune-304, kunokusebenza okuhle mayelana nobunzima obuphezulu.Ubulukhuni obuphakeme kakhulu bungafinyelela cishe amadigri angu-H620, okungenakufinyeleleka ngezinto ezijwayelekile.301 ubulukhuni

Isilinganiso singahlukaniswa ngamadigri angu-HV200 ~ HV620 degrees, futhi ubulukhuni obungaphansi kwama-degree angu-420 bungabiwa ngezinto ezingu-304!Mayelana nokumelana, iphansi kune-420HV, okungcono i-304 impahla, ngoba

Ibhande lensimbi engagqwali elingu-304 linekhabhoni ephansi kakhulu, engcono kunento engama-301 ngokwezinto zokumelana!

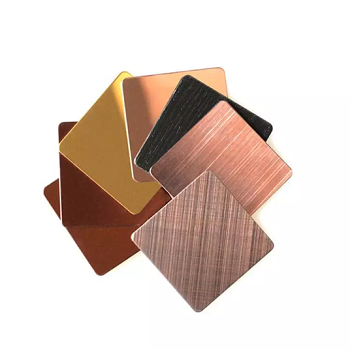

Usayizi Owenziwe Ngokwezifiso 201 / 301 / 304 / 316 / 430 Ipuleti Lensimbi Engenasici / Ishidi

Ukwakheka kwamakhemikhali: C: ≤0.15, Si: ≤1.0, Mn: ≤2.0, Cr: 16.0~18.0, Ni: 6.0-8.0, S: ≤0.03, P: ≤0.045

I-SUS301 (17Cr-7Ni) insimbi engagqwali ingathola amandla aphezulu ngemva kokusebenza okubandayo.301 insimbi engagqwali uhlobo lwensimbi engagqwali ye-austenitic metastable.Ngaphansi kwesimo sesixazululo esigcwele, sinakho

inohlelo oluphelele lwe-austenite.Phakathi kwezinsimbi ezingenasici, i-301 iyinsimbi okungenzeka kakhulu ukuthi iqiniswe ukuguqulwa okubandayo.Amandla nobulukhuni bensimbi kungathuthukiswa ngokucubungula okubandayo kwe-deformation, futhi izidingo zigcinwa.

ipulasitiki nokumelana, okuhambisana nale nsimbi inokumelana nokugqwala okuhle kakhulu ngaphansi kwezimo zomoya, kodwa ukumelana nokugqwala okungekuhle ekwehliseni imidiya, ukumelana nokugqwala okungekuhle emithonjeni yamakhemikhali efana ne-asidi, i-alkali nosawoti,

Ngakho-ke, akunconyelwe ezindaweni ezinokhahlo ezonakalisayo.I-301 isetshenziswa kakhulu ezimeni zokusebenza ezibandayo ukuze yamukele imithwalo ephezulu, kodwa futhi inethemba lokunciphisa isisindo semishini kanye nezingxenye zemishini ezingagqwali.

ivamise ukugoqwa kahle, nokubekezelela ukujiya okungu-0.01mm-0.005mm.I-SUS301 yensimbi engagqwali Ngenxa yokuqina kwayo okuphezulu nokunwebeka okuhle, iziphethu zasentwasahlobo zonke ziyasetshenziswa

301 ibhande lensimbi engagqwali.Izimoto zikaloliwe, izithuthi zamabhande, amabhawodi namantongomane, iziphethu, njll. Izinhlamvu zewashi, ukusetshenziswa kwebhande lensimbi elinembe kakhulu, njll.

Izinkinga zokukhiqiza kanye nezindlela zokucubungula ze-stainless steel strip

I-Stainless steel strip ilula ukugqwala emanzini nasemoyeni.Izinga lokugqwala kwe-zinc emkhathini liyi-1/15 kuphela yezinga lokugqwala kwensimbi emkhathini.Insimbi enama-galvanized isetshenziselwa ukugcina ipuleti lensimbi elinesendlalelo esiminyene esinama-galvanized.Vikela ekugqwaleni.Ibhande lensimbi engagqwali libhekisela ebhandeni lokuthutha elenziwe ngensimbi ye-carbon njengento edonsayo kanye nelungu elithwele lesithumeli sebhande.Ingasetshenziswa futhi ukuhlanganisa izimpahla.Kuyisidingo samabhizinisi ahlukahlukene agingqa insimbi ukuze ajwayele ukukhiqizwa kwezimboni kwemikhiqizo ehlukahlukene yensimbi noma yemishini emikhakheni ehlukene yezimboni.Futhi kukhiqizwa ipuleti lensimbi elincane nelide.

Ububanzi bomugqa wensimbi engagqwali bungaphakathi kuka-1300mm, futhi ubude buhluke kancane ngokuya ngosayizi womqulu ngamunye.Insimbi ye-strip ngokuvamile inikezwa ngamakhoyili, anezinzuzo zokunemba kobukhulu obuphakeme, ikhwalithi enhle yokubukeka, ukucutshungulwa kalula, nokonga idatha.Imichilo yensimbi ihlukaniswe yaba yinsimbi evamile yomugqa kanye nensimbi yekhwalithi ephezulu ngokuya ngezinto ezingavuthiwe ezisetshenziswayo, futhi umucu wensimbi ogoqelwe oshisayo kanye nomugqa wensimbi obandayo zihlukaniswa ngokwendlela yokucubungula.

I-Stainless steel strip inomphumela omkhulu, ukusetshenziswa okubanzi, kanye nemikhiqizo yensimbi ehlukahlukene.Ihlukaniswe yaba i-hot-rolled steel strip kanye ne-cold-rolled steel strip ngokuya ngendlela yokucubungula;ihlukaniswe yaba yi-strip yensimbi emincane (ubukhulu obungaphansi kuka-4mm) kanye ne-strip yensimbi ewugqinsi (ubukhulu obukhulu kuno-4mm) ngokusho kobukhulu, futhi ihlukaniswe ibe yi-strip yensimbi ebanzi ngokobubanzi (ububanzi obukhulu kuno-600mm) Nemicu yensimbi emincane (ububanzi abukho ngaphezu kuka-600mm ), imichilo yensimbi emincane ihlukaniswe yaba yimichilo yensimbi emincane egoqekayo kanye nokusika imichilo yensimbi emincane emicu yensimbi ebanzi.Ngokubukeka kwabo, bahlukaniswe ngokubukeka kokuqala kokugoqa kanye nokubukeka kwe-plating (ukugqoka).Amabhande ensimbi ahlukaniswe abe ajwayelekile futhi akhethekile (njengama-hulls, amabhuloho, izigubhu zikawoyela, amapayipi ashiselwe, okupakishwayo, izimoto ezizikhiqizayo, njll.) amabhande ensimbi ngokuya ngokusetshenziswa kwawo.

izinto zokukhiqiza i-stainless steel strip

1. Ngaphambi kokuqala umshini, hlola ukuthi izingxenye ezijikelezayo zemishini kanye nezingxenye zikagesi ziphephile futhi zithembekile.Uma kukhona okungahambi kahle, thola abasebenzi abafanelekile ukuze bakulungise kusenesikhathi.

2. Idatha esendaweni yokusebenza kufanele ipakishwe kahle, futhi akumele kube nezithiyo ephasejini.

3. Abaqhubi kufanele bagqoke izingubo zokusebenza, babophe ama-cuffs namakhona baqine, bagqoke amakepisi okusebenza, amagilavu, nezibuko zokuzivikela.

4. Lapho ushayela, akuvunyelwe ukuhlanza, ukufaka uphethiloli nokulungisa izinto zokusebenza, noma ukuhlanza indawo yokusebenza.Ungathinti ibhande lensimbi nezingxenye ezijikelezayo ngezandla zakho lapho ushayela.

5. Akuvunyelwe ukufaka izinto noma ezinye izinto emshinini noma ikhava yesondlo ngenkathi ushayela.

6. Uma usebenzisa i-electric hoist hoist, imithetho yokusebenza kokuphepha kwe-electric hoist kufanele ilandelwe, intambo yocingo kufanele ihlolwe ukuthi isesimweni esihle yini futhi ihhuku kufanele ilengiswe.Lapho uphakamisa ibhande lensimbi, akuvunyelwe ukutsheka noma ukulenga ibhande lensimbi emoyeni ngesikhathi sokukhiqiza.

7. Uma ukusebenza sekuphelile noma amandla enqanyulwa phakathi nendawo, ukunikezwa kwamandla kufanele kuvinjwe ngokushesha.

Ibhande lensimbi engagqwali (umcu).

Insimbi engagqwali enezimpawu zokuthengisa.Insimbi engagqwali eqinile estakiwe.Inomsebenzi omuhle wokwakha kanye nokushisela okuhle kakhulu, futhi ingasetshenziswa njengempahla yamandla aphakeme kakhulu embonini yenuzi, ezimbonini zezindiza kanye nezomkhathi.Ngokuya ngokwakhiwa, ingahlukaniswa ngochungechunge lwe-Cr (SUS400), uchungechunge lwe-Cr-Ni (SUS300), i-Cr-Mn-Ni (SUS200) nochungechunge oluhlukene lokuqina (SUS600).

Ifekthri inikezela ngepuleti/ishidi lensimbi engagqwali

200 uchungechunge—chromium-nickel-manganese austenitic steel stainless

300 uchungechunge—chromium-nickel austenitic insimbi engagqwali

301-I-ductility enhle, esetshenziselwa imikhiqizo ebunjiwe.Ingabuye iqiniswe ngokushesha ngomshini.Ukushisela okuhle.Ukumelana nemihuzuko namandla okukhathala kungcono kunensimbi engagqwali engama-304.

302—Ukumelana nokugqwala kuyafana nalokho kwe-304, futhi amandla angcono ngenxa yokuqukethwe kwekhabhoni ephezulu kakhulu.

303—Ngemva kokwengeza inani elincane lesulfure ne-phosphorus, kulula ukusika kunama-304.

304—okungukuthi, 18/8 insimbi engagqwali.Uphawu lokuthengisa lwe-GB ngu-0Cr18Ni9.

309—Uma kuqhathaniswa no-304, inokumelana nezinga lokushisa okungcono.

I-316-Ngemva kuka-304, ibanga lensimbi lesibili elisetshenziswa kakhulu, elisetshenziswa kakhulu embonini yokudla kanye nemishini yokuhlinza, ingeza isici se-molybdenum ukuthola isakhiwo esikhethekile esimelana nokugqwala.Ngenxa yokuthi inokumelana kangcono ne-chloride corrosion kune-304, iphinda isetshenziswe "njengensimbi yomkhumbi".I-SS316 ivamise ukusetshenziswa emishinini yokubuyisela uphethiloli wenuzi.Insimbi engagqwali engu-18/10 ngokuvamile nayo ihlangabezana naleli zinga lesicelo.

321—Ngaphandle kokwengezwa kwe-titanium, okunciphisa ubungozi bokugqwala kwe-weld weld, eminye imisebenzi ifana ne-304.

400 uchungechunge—insimbi engagqwali ye-ferritic ne-martensitic

408—Ukumelana nokushisa okuhle, ukumelana nokugqwala okubuthakathaka, 11% Cr, 8% Ni.

409—uhlobo olushibhile kakhulu (lwaseBrithani naseMelika), oluvame ukusetshenziswa njengepayipi lombhobho wemoto, insimbi engagqwali ye-ferritic (insimbi ye-chrome).

410—I-Martensite (insimbi ye-chromium enamandla aphezulu), ukumelana nokugqokwa okuhle, ukumelana nokugqwala okungekuhle.

416—Engeza isibabule futhi uthuthukise umsebenzi wokucubungula idatha.

420—“ibanga lethuluzi” insimbi ye-martensitic, efana nensimbi engagqwali yakudala njenge-Brinell high chromium steel.Ibuye isetshenziselwe imimese yokuhlinza, engakhanya kakhulu.

430-Insimbi engagqwali ye-Ferritic, yokuhlobisa, njengezinsiza zemoto.Ukwakheka okuhle kakhulu, kepha ukumelana nezinga lokushisa okungekuhle kanye nokumelana nokugqwala.

440—Insimbi yethuluzi lokusika elinamandla aphezulu enokuqukethwe kwekhabhoni ephakeme kancane.Ngemuva kokwelashwa okufanele kokushisa, amandla aphezulu esivuno angatholakala.Ukuqina bungafinyelela ku-58HRC, ehlukaniswa njengensimbi engenasici eqinile.Isibonelo esivame kakhulu "ama-razor blades."Kunezinhlobo ezintathu ezivame ukusetshenziswa: 440A, 440B, 440C, kanye ne-440F (uhlobo lokucubungula olulula) kwabanye.

500 uchungechunge—insimbi ye-chromium alloy ekwazi ukumelana nokushisa.

600 uchungechunge—Ukuqoqwa kwe-Martensite kuqinisa insimbi engagqwali.

630—Uhlobo olusetshenziswa kakhulu lwesitaki oluqinisa insimbi engagqwali, ngokuvamile olubizwa ngokuthi 17-4;17% Cr, 4%.Ni.

Isikhathi sokuthumela: Aug-06-2020